Technical material

For technical materials (industrial materials/ functional materials), various tests are performed according to the usage of the materials.

Tests related on emergency management and safety evaluation

Tests for materials related on emergency management and safety evaluation are provided.

Tests for high visibility safety clothing

High visibility safety clothing are clothes that enhance their visibility using fluorescent fabric and retroreflective material.

The clothing is expected to decrease car accidents against road workers because the workers wearing the clothing can attract the driver’s attention.

Representative test standards

- ISO 20471 High visibility clothing

- JATRAS001 High visibility clothing for children

- JIS T 8127 High visibility warning clothing

- JSAA2001 High visibility clothing for general use

Main test contents

Tests corresponding to high visibility safety clothing standards are divided into 3 main categories.

①Design

| Area measurement (Class evaluation) |

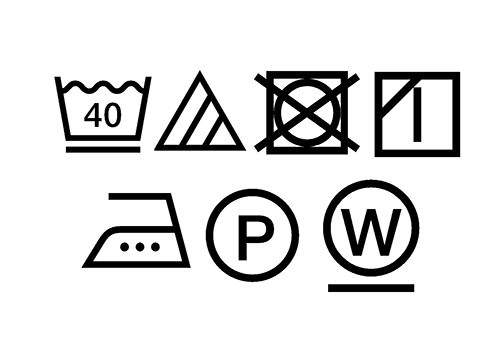

Design | Care Label |

|---|---|---|

| The area of fluorescent fabric and retroreflective material used in products are measured. |

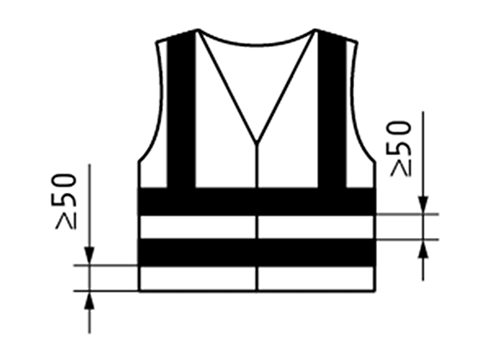

Inspects whether the design of the product meets the requirements of the standard. Example) ・Whether the width of the reflective material is more than 50mm. ・Whether the fluorescent fabric is going around the torso part. |

Inspect whether the care label symbol, size notation, and manufacturer information have any errors. |

|

Corresponds to any class defined in the standard from the result of the measured area. |

An example design in JIS T 8127 |

An example of Indication symbol |

②Fluorescent

| Colorimetry | Fabric | Physiological property |

|---|---|---|

| The color of fabric is measured. (XY color coordinate and luminance) ・Original fabric ・Post-light ・Post-aged deterioration (Washing, Dry-cleaning) |

Fabric test such as color fastness and physical property is conducted. | Degree of moisture penetration is measured in the test of moisture penetrant resistance, then comfort of product is evaluated. |

|

|

③Retroreflective material

Measurement of reflective luminance

| Measurement after endurance test | Measurement after aged deterioration |

|---|---|

| ・Abrasion test ・Temp. change test ・Bend test ・Cold bend test ・Rain test Reflective luminance is measured after the above endurance tests. |

・Washing test *Temp. condition, process cycle and solvent types are designated by clients, or depends on the product’s care label symbol. |

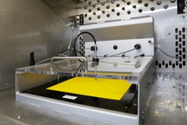

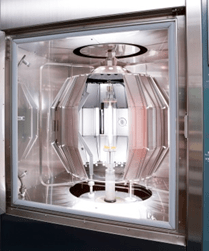

Rain test(Reflective luminance is measured under rain environment inside the test machine such the photo.) |

|

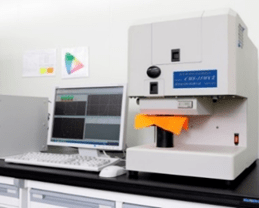

Colorimetry test

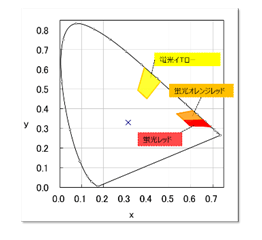

Color coordinate and color luminance are measured using fluorescent color spectrophotometer whether they meet the color requirements of standards.

Besides, the test is also available for any surface of various materials beyond textile fabrics, if conditions were met even not standards for high visibility safety clothing.

Test standard mainly used

- ISO 20471 High visibility clothing

- JIS Z 9103 Safe color and safe symbol

- JIS T 8127 High visibility safety clothing

- JIS Z 9107 Safety colors and safety signs

(rules on general and phosphorescence materials) - JIS Z 9097 Tsunami evacuation guidance

(rules on phosphorescence materials)

Main test contents

・XY color coordinate

・Luminance

・Munsell value

These three things and others can be measured.

|

|

|

|

|

Fluorescent color spectrophotometer |

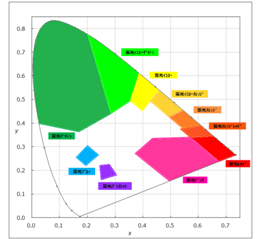

JIS T 8127 chromaticity chart |

JSAA 2001 chromaticity chart |

Reflective property test

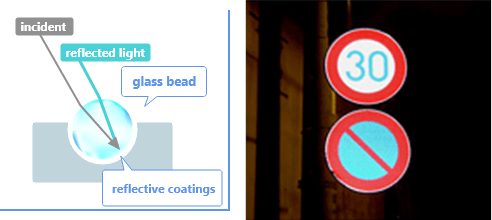

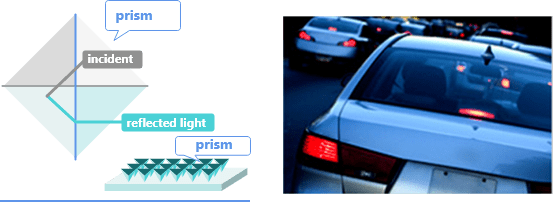

Retroreflective material

Mainly when the light hitting the material surface (incident light) bounces off, it refers to a material that allows the reflected light to return more strongly in a direction almost along the path of the light.

There are several types, mainly 2 types, bead type and prism type.

It is used depending on the conditions and environment such as the installed location.

Main usage

| Bead type | Prism type |

|---|---|

| High visibility safety clothing, safety band (harness), sport wear, shoes etc. | High visibility safety clothing, safety band (harness), road sign, reflective plate for vehicle and bicycle, etc. |

Bead type

Prism type

Test standard mainly used

- ISO 20471 High visibility clothing

- JIS T 8127 High visibility warning clothing

- JIS Z 9117 Retroreflective materials

Main test contents

In the visual retroreflection performance measurement method (Nissenken method), measurement and determination of the recoil reflectance performance are performed by comparing the NA-NC class retroreflective material with the test sample, which was determined by the measurement method of JIS Z 9117.

It also supports small-area samples such as brand logos and pipes.

In addition, the tests specified in JIS T 8127 High Visibility Safety Clothes can also be conducted at the affiliated institution.

Are all retroreflective materials needed to conduct

retroreflective test after endurance tests?

Standards for high visibility safety clothing (ISO 20471, JIS T 8127)

need to conduct tests after endurance tests.

In this case, test contents can be recommended based on

usage and purpose.

Phosphorescence test

Phosphorescence mechanism

Electron inside phosphorescence material is energized after irradiation of specific light to the material because of reaction against ultraviolet range in the light. In this moment, the electron has swift movement repeatedly between low (ground state) and high (excited state) in extremely high velocity. In this case, it seems that the material is looked giving out light from its inside because occurred energy between the above swift movement is emitted as light energy to become low (ground state).

Test standard mainly used

- JIS Z 9107 Safety colors and safety signs

- JIS Z 9097 Tsunami evacuation guidance

- E 010-08 FESCJ

(Fire Equipment and Safety Center of Japan) standard - NSA Vehicle control No. 7-1

NSA (Nippon Signs Association) standard

Main test contents

| Phosphorescence luminance measurement | Endurance test |

|---|---|

|

|

|

| After leaving the sample in a dark place for a certain period of time so the sample does not emit light (ground state), keep illuminating for a certain period of time with a fixed fluorescent light (D65) or xenon arc light etc. After a certain period, shut off (turn off) the light source and measure the phosphorescence luminance of the sample that has phosphorescent performance. |

Phosphorescence luminance measurement test is conducted again after endurance tests such as rubbing, weather, anti-chemical and temperature change, based on sample’s characteristics. |

Are test contents available to consult

when we offer phosphorescence material test?

Phosphorescence material test has various types

depending on evacuation signs

and miscellaneous goods because type of light source,

irradiation time and measurement time are different

We can provide and recommend you suitable test based on your requests.

Please don’t hesitate to ask us.

Vehicle

Fabric test

Flammability test for inner material of motor vehicle is conducted.

Contact Us

Inquiries about services

![]()

For inquiries about testing services.

Inquiries for OEKO-TEX®

![]()

For inquiries about OEKO-TEX® certificate.

Downloads

![]()

For more information, please download the documents about our testing services.

FAQ

![]()

For the frequently asked questions.

Inquiry by phone

Inquiries about tests, laws and standards etc.

General affairs・Management divisions

Business hours 9:00~17:00

(Mon. – Fri. except national holidays)