Garment test

For garment inspection, check appearance, sewing and confirm the label items in line with Household Goods Quality Labeling.

Garment test

Garment test

Appearance, sewing, and raw materials

We check whether the garment have any defects. We check to see if there are left-right asymmetry,twist etc. (appearance), frayed seam, seam slippage etc. (sewing), if using a fabric that matches the garments characteristics, whether accessories such as buttons etc. with burrs and sharp projections are used etc. (material), to make sure it doesn’t interfere with wearing the garment.

Care label

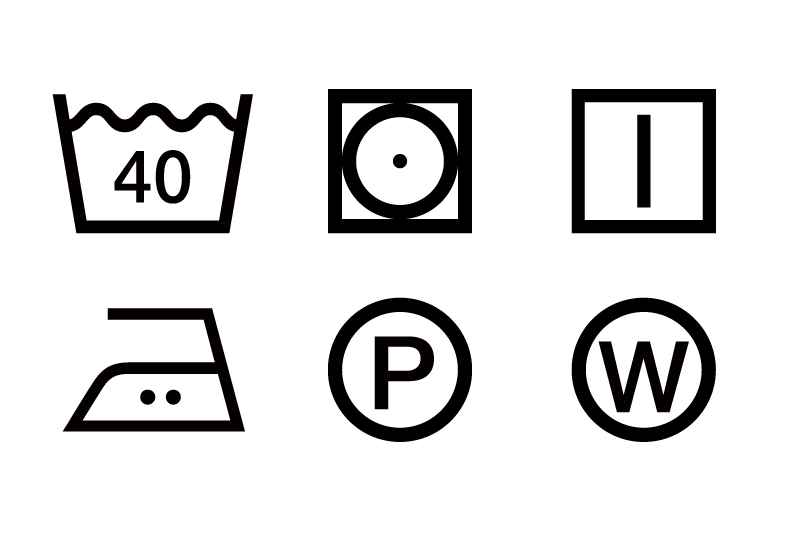

Overprotective care label symbol

For textile products, it is necessary to indicate the fiber composition and care instructions in accordance with “Household Goods Quality Labeling Act” for consumers to identify the quality.

The same goes for leather clothing.

The care label symbol must be appropriate for the garment, but it is also inappropriate to indicate unnecessary weak processing.

Exaggerated misunderstanding recognition

In a case of displaying the country of origin or the garments functionality, it is necessary to indicate it in accordance with “Act against Unjustifiable Premiums and Misleading Representations”. Therefore, we check whether these indications are displayed. This is performed to prevent indications that are disadvantageous for the customers such as making the garment quality unreasonably high (indicating functionality, although functionality finishing was not processed etc.).

Functionality

It is necessary to be careful not to conflict with “Act on Securing Quality, Efficacy and Safety of Products Including Pharmaceuticals and Medical Devices”.

For example, medical effects such as “Stiff shoulder can be healed” and “Promote blood circulation” cannot be shown.

(Excluding pharmaceuticals, quasi drugs and medical devices.)

Dimensional stability and Appearance change

We check whether there is a problem, by washing and dry cleaning the product. The processing method basically follows the care label symbol; however, if there is an agreement with the delivery destination, that should be the priority. Even if there was no problem in the test of a single fabric, there may be a problem when making it into a garment and for that reason it is very important to actually wash it.

Examples

・The lining of the skirt and dress is showing because the dimensional change rate of

the outer fabric and lining are different.

・Bleeding due to color scheme, waviness on the seam (seam puckering), deformation, peeling of the coating, excessive shrinkage & overstretched of the dimensions.

Functionality

OEKO-TEX®

OEKO-TEX® Laboratory

4-2-8, Tateishi, Katsushika-ku, Tokyo, 124-0012 JAPAN

Tel:+81-3-5875-6055

Fax:+81-3-5875-6331

E-mail:oeko-tex@nissenken.or.jp

Product inspection

Product inspection

Sampling Inspection

Extract some garments in each color and each size, then compare these garments with specifications in sewing, appearance, function, dimension and attachment (accessories) before inspecting mass product garment.

All products inspection

Inspect appearance such as dirt and sewing defect, also provide inspection in accordance with the customer’s requests.

*Available contents differ between Japan and overseas. Please refer to “Available work” for details.

Needle detection

We check the double gate conveyor type meter inspection machine one by one, to check if there are any dangerous objects such as needle mixed in the product.

X-ray check

Products that use metal that is not compatible with a conveyor type meter or bulky products such as clothing, bags, shoes and miscellaneous goods that does not pass through is checked visually with monitor whether there is any dangerous objects mixed in.

Secondary process

Press

Conduct suitable press for fabrics using tunnel finisher, dummy pressing machine and pants toppers.

Finishing press

Conduct suitable finishing press for the fabrics texture and design.

Product correction

Modify the dirt, scratches and foreign fiber.

Also, we correspond in replacing the name tags and modify sewing defects.

Nissenken proposes the best combination upon the customer’s request. Below

Clothing

Needle detection

- Inspection + Needle detection

→ Equivalent to normal “full inspection” - Inspection + X ray check

Bulky items such as down jackets and coats that cannot pass through the Needle detector. - Needle detection only

①For products inspected at other companies.

②For products made in a well-equipped factory with a production system in place and the client states that only factory inspection is needed. the clients states that factory inspection only. - X ray check only

①For products inspected at other companies.

②For products made in a well-equipped factory with a production system in place and the client states that only factory inspection is needed. the clients states that factory inspection only.

Staff memo of inspection center

We may receive requests to change the work we’re following, depending on the proportion of defective products of the sampling inspection.

(e.g.)

First step: Sampling Inspection

Second step:Full inspection・Full needle detection・X ray check or Full inspection.

After inspection and needle detection is carried out at NQ inspection centers in China etc., can you hang it and apply press finishes before delivering to customers in Japan?

For products shipped from overseas in the state of folding and packing, we can hang and apply press finishes at our NQ Tokyo Inspection Center.

Other products

Other products

- Towel, hats, etc

- Shoes, bags, etc.

- Bedding, rugs, curtains, etc.

- Stuffed animals etc

- Inspection + X ray check

→Equivalent to normal full inspection - X ray check only

Due to nail or m etal buttons not passing in response to the meter reading machine especially for shoes and - Sampling inspection + Full X ray check

*Due to nail or m etal buttons not passing in response to the meter reading machine especially for shoes and bags, we recommend either menu depending on the situation.

Nissenken garment inspection centers

| Country | Inspection center | Inspection | Needle detection |

X-ray check |

Address | Contact |

|---|---|---|---|---|---|---|

| China | Yantai Laboratory | 〇 | 〇 | East and West Technology Park West, No. 29 Haite Road, Zhifu, Yantai, 264000 CHINA [Yantai Nissenken Textile Inspection Co., Ltd.] |

Tel: +86-535-602-2163 / +86-535-602-2170 E-mail: yantai-seihin@nissenken.or.jp |

|

| Nantong-Chong Chuan Laboratory |

〇 | 〇 | 〇 | 3F 32, Zilang-Road, Development zone, Chongchuan, Nantong, Jiangsu, 226008 CHINA [Nantong Jima Inspection & Logistic Center ] |

Tel: +86-513-6896-2818 E-mail: sugawa@nissenken.or.jp |

|

| Nantong Laboratory |

〇 | 〇 | 〇 | Industrial District, Xing Rem, Tong Zhou, Nantong, Jiangsu, 226371 CHINA [ China C-Nissenken Inspection Co., Ltd ] |

Tel: +86-513-8661-1710 E-mail: nantu-seihin@nissenken.or.jp |

|

| Nantong Gangzha District Inspection Center |

〇 | 〇 | No. 398 Chang Jiang Bei Road, Gangzha, Nantong, Jiangsu, 226000 CHINA [Nantong Ritong Technology Development Co., Ltd.] |

Tel: +86-513-6990-3500 E-mail: gangzha@nissenken.or.jp |

||

| Japan | Tokyo Inspection Center |

〇 | 〇 | 〇 | 2-10-1, Niibori, Edogawa-ku, Tokyo, 132-0001 JAPAN |

Tel: +81-3-6231-8411 E-mail: tokyo-kenpin@nissenken.or.jp |

※Secondary finishing and retouching are available at our Tokyo Inspection Center.

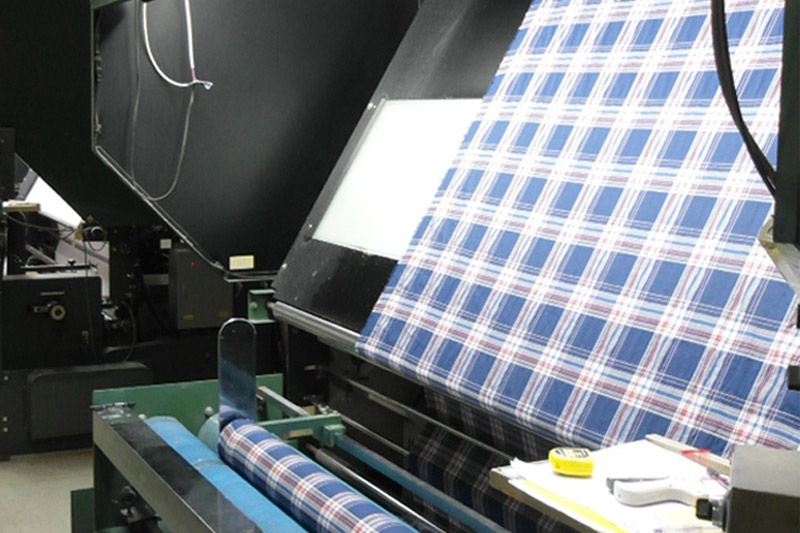

Fabric inspection

We carry out visual inspection of domestic and imported rolls of fabric. The inspection contains confirmation of color and texture from measurement of width and length, weaving defects (warp thread breakage, weft thread breakage, weaving bar, weaving different fibers and foreign objects, pinhole defects etc.) finishing defects (wrinkle, oil stain, uneven dye, print defects etc.) with a winding inspection machine and display the fault points with a tag. The inspection is carried out to prevent pattern layout of the fault point before sewing and retouching.

Contact Us

Inquiries about services

![]()

For inquiries about testing services.

Inquiries for OEKO-TEX®

![]()

For inquiries about OEKO-TEX® certificate.

Downloads

![]()

For more information, please download the documents about our testing services.

FAQ

![]()

For the frequently asked questions.

Inquiry by phone

Inquiries about tests, laws and standards etc.

General affairs・Management divisions

Business hours 9:00~17:00

(Mon. – Fri. except national holidays)